Message from the Co-COO

Looking Back on the First Stage of Our Initiatives to Realize Our Long-Term Management Vision

We have just completed the first stage of our initiatives to realize our long-term management vision, set for fiscal 2031. Looking back on the past three years, I feel Tsumura’s domestic business is reaching an important turning point. Aside from structural changes dictated by an inflationary economy on top of the spread of AI, the effects of shipment limitations during the pandemic and the government’s 2024 drug price revisions were so immense on the Tsumura Group that we have begun adapting our business strategy and revising our investment plan.

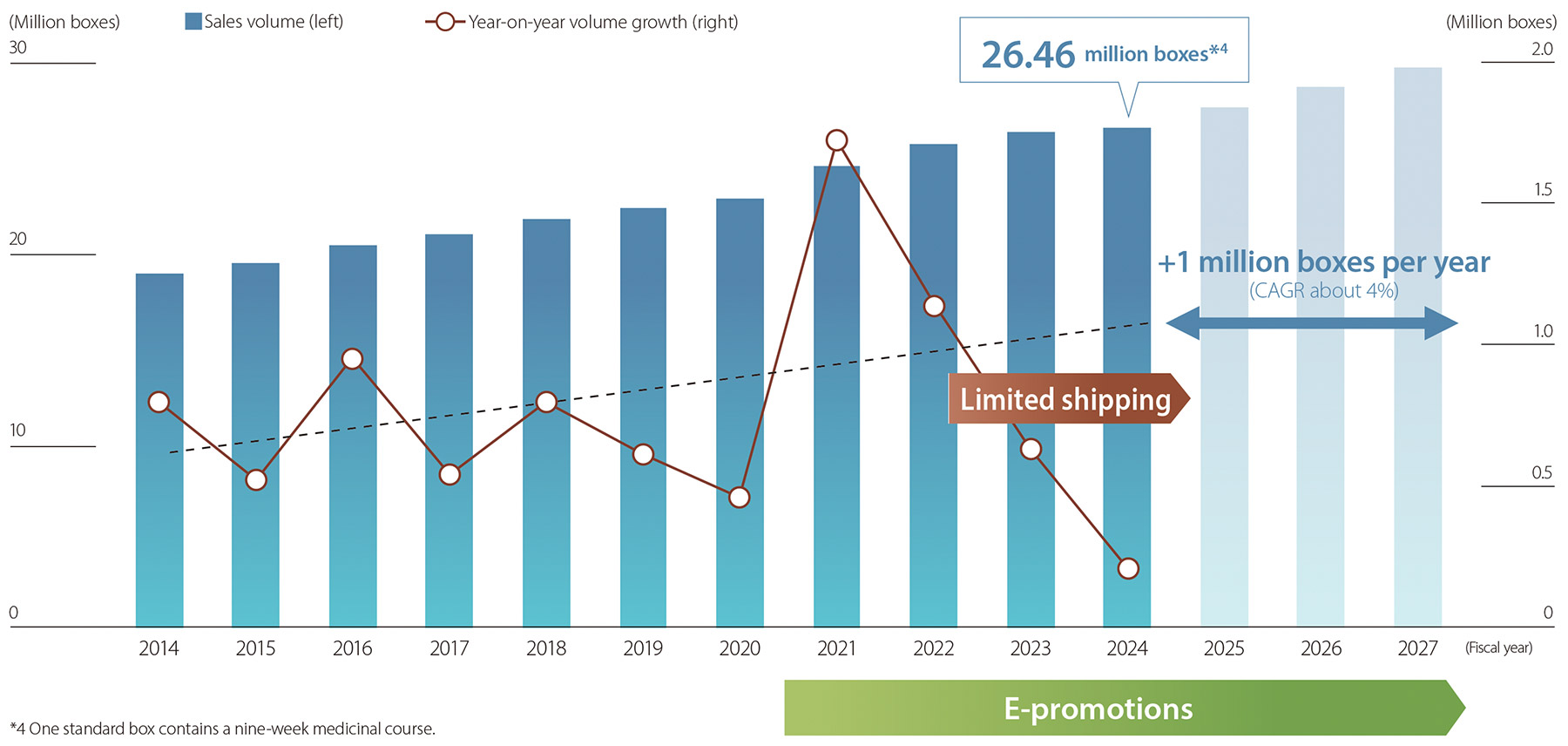

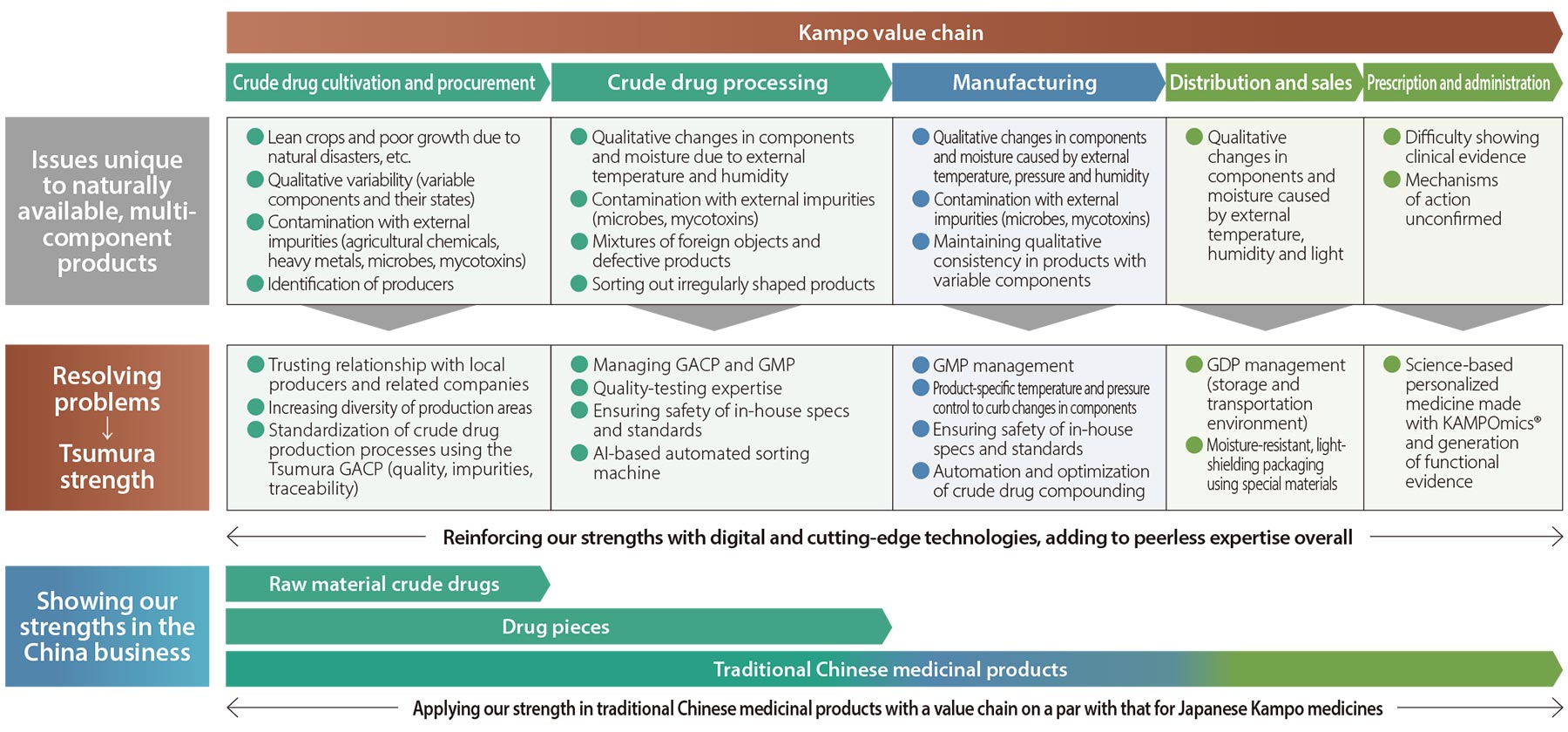

Under the price revisions, 66 of Tsumura’s prescription Kampo formulations were designated as money-losing products and became eligible for price reevaluation, which boosted earnings to achieve our three-year goal in terms of value. We fell short of the volume target, however, as we had to limit shipping starting in 2022 due to the pandemic. Even considering external factors, I understand this left much to be desired. I take the price reevaluation eligibility of our money-losing products, which were affected by higher prices for raw materials and the like, as an encouragement from the government that we should maintain or even reinforce the reliability of our supply system. Based on that understanding, we will continue expanding our production capacity, continuing on from our first medium-term management plan, and accelerate investment for higher productivity so we can enhance our supply systems.

Construction costs, with our production building as a prime example, have more than doubled since 2022, when our long-term management vision was written, due to higher material costs and other factors. For large projects in terms of budget scale, the Board of Directors has been putting hours into in-depth discussions to confirm our investment amounts, recoupment periods, and specs for invested equipment are justified. Some larger projects were postponed into the second medium-term management plan. Tsumura has introduced standards, including a hurdle rate for internal rate of return and net present value, to determine whether a given investment project is worth the money. It allows us on the board, including our outside directors, to make clear, rigorous assessments. In addition, floor employees are now more conscious of the targeted effects and costs they can anticipate in the idea stage of a given business, as well as equipment design.

During the first medium-term management plan, we made steady progress with our initiative to better inform physicians, with results to scale expansion of our business during the second medium-term management plan. Specifically, we increased the percentage of physicians prescribing 10 or more prescription Kampo formulations, and achieved our goal of at least half of clinicians in fiscal 2024. I take that figure as proof that Kampo formulations have spread enough on the healthcare front lines to encourage physicians to select and prescribe them depending on the physical condition and symptoms of the patient. Looking closely, however, there are large regional and departmental disparities in the numbers of prescriptions. While addressing this, we will continue working to increase the percentage of physicians prescribing 10 or more prescription Kampo formulations.

We will boldly rise to the challenge of continuously growing the Kampo market and investing in production equipment to realize the long-term management vision we share.

Enhancing Supply and DX Systems for Reliability and Elevated Customer Experiences

When we wrote our long-term management vision in 2022, we designated the first stage as a period for advance investment and the second stage as full-scale operation of that new equipment. With the larger investment plan postponed, as I mentioned, we revised our designation of the second stage as an investment period for equipment and scale expansion to enhance reliable supply. This will increase capital expenditure, depreciation, amortization, and labor costs, and as a result, we project a transient drop in our operating profit margin and ROE. For the three-year period ending in fiscal 2027, we plan to assure ROE consistently above 7%, the cost of shareholders’ equity, and will maintain strategic investment.

To advance our domestic business to a growth stage over the coming three years, we will have to speed up and make both qualitative and quantitative improvements to our efforts to better inform physicians of Kampo formulations and prescriptions. This is because in the near future physicians will be more likely to diagnose each patient’s pattern*1 and choose from Kampo medicines based on the crude drug components they think are best for the physical condition and symptoms of the patient. With this emerging trend in mind, we will shift to better information supply by more accurately understanding the needs of each physician. Specifically, we will do this using a hybrid information supply system combining an e-promotion platform based on digital technology with in-person contact by our MRs. We will increase data-based approaches to customers to optimize customer insight analysis and digital content.

On the personnel front, we will use our Kampo Meister system to help our MRs sharpen their knowledge of Kampo medicine, and provide physicians with more useful information based on that deeper understanding of their needs. In research and development, we will build evidence in three priority areas*2 closely related to social challenges. We will also advance our scientific study of pre-symptomatic diseases and patterns to the clinical research stage and make the most of the evidence we obtain from that research.

Alongside our effort to build sales volume, we are currently working on additional systems enhancement to assure reliable supply, which includes an increase in production capacity. As a longer-term possibility, we are considering S&OP*3 that optimizes the entire crude drug supply chain in terms of profit levels. At this time, however, I understand we are in the stage of volume-based improvement and expansion. We developed and introduced a planning system for compounding crude drugs during the period of the first medium-term management plan, but during the second, we will realize seamless operations, from sales planning to crude drug cultivation and procurement planning.

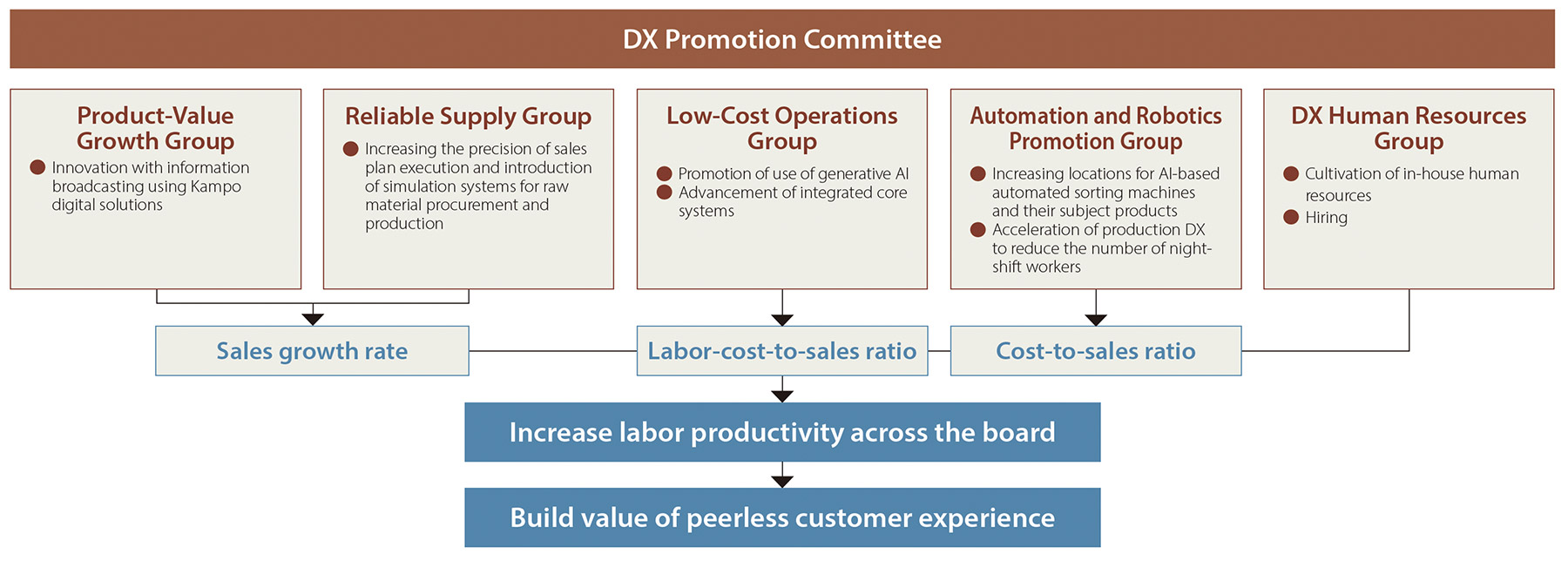

As I previously mentioned, digital transformation (DX) will be key to the success of our initiatives to cultivate our businesses and optimize overall work processes. In April 2025, we established our DX Promotion Committee, which oversees the promotion of DX across the board. It is the beginning of a project to build the value of a peerless customer experience that the Group has envisioned. As the committee chair, I have organized five specialist groups (see the chart below) and other sub-groups. In addition to application of digital technologies, I think the value of a peerless customer experience depends on interorganizational collaboration and the initiative of each employee. So I, the committee chair, and the leaders of the five specialist groups meet and talk directly to break the complacency with status quo that organizations can easily fall into. The DX Promotion Committee will take on the job of identifying issues that are hindering labor productivity and trigger organizational reform.

To realize our long-term management vision, I understand that skilled helmsmanship in the second stage, meaning the second medium-term management plan, is extremely important. I will play the role of flagger steering initiatives to achieve both qualitative and quantitative goals to embody what the Tsumura Group should be in the future, as well as ideal work styles for the future.

- ※1 Kampo medicine’s way of demonstrating evidence of the patient’s condition (considering individual differences in physical constitution, physical strength, resistance, and presentation of symptoms)

- ※2 Geriatric health, cancer (supportive care), women’s health

- ※3 Sales and Operations Planning is a system in which the management team makes plans for production, sales, desired inventory levels, operating profit, and the like based on actual sales data, and each business segment executes the plans.

Numerical Targets of Our Long-Term Management Vision

DX Promotion System

Actual Sales of Prescription Kampo Formulations and Plans