Recycling use of resources

Policy for Water Resources

Changes in water resources affect the entire supply chain of raw material crude drugs from cultivation to procurement, including changes in growing conditions and yields of raw material crude drugs, increases in the prices of crude drugs, and effects on the quality of raw material crude drugs and prescription Kampo products.

Moreover, the manufacturing process for prescription Kampo products requires a large amount of water resources. Since our production sites in Japan primarily use groundwater, changes in water resources affect the stable supply of our drug products.

The Tsumura Group strives to mitigate water resource risks by strengthening its Kampo value chain.

Goals and Progress

| Item |

Progress (FY2022 Results) |

Target |

FY2024 targets (reference year: FY2020) |

|---|---|---|---|

| Per-unit water intake* | 6% increase compared to the reference year |

〇 Shizuoka Plant・Ibaraki Plant |

10% reduction |

〇・・・Tsumura standalone figures

* Water intake per unit = Water intake (t)/production volume of extract granules for pharmaceutical products (t)

Key initiative

A new facility to reuse water used in the manufacturing process was introduced in the Third SD Building at the Ibaraki Plant,we have implemented a system for reusing cooling water from the extracted liquid condensation process for Kampo extract at four plants in Shizuoka, Ibaraki, Shanghai, and Tianjin. In fiscal 2022, these four plants accounted for around 96% of the entire wastewater volume for the Group.

Environmental Performance Data

Policy for Waste

The Tsumura Group is working to renew the 3Rs (reduce, reuse, recycle) and create mechanisms for resource circulation. Most of the industrial waste generated by the Group is residue left over from extract produced during the Kampo formulation manufacturing process (crude drug residue).

Therefore, we are particularly focused on efforts to make use of crude drug residues. The Crude Drug Residue Subcommittee is leading this initiative.

Goals and Progress Results

| Item |

Progress (FY2022 Results) |

Target |

FY2024 targets (reference year: FY2020) |

|---|---|---|---|

| Plastic usage | We are now selecting and evaluating packaging materials. | 〇 | 10% reduction |

| Industrial waste discharge intensity* | Study under way to utilize crude drug residues | 〇 | 50% reduction |

〇・・・Parent

* Industrial waste discharge intensity = Industrial waste discharge (t)/production volume of extract granules for pharmaceutical products (t)

Key initiative

Some crude drug residues are also traded for a fee, and the Group sells it for uses such as biomass fuel, which helps to reduce CO2 emissions from thermal power stations. Other residues are also 100% recycled by composting and so forth.

In parallel with resource recycling, we are also focusing on creating better mechanisms for resource circulation. Crude drug residue contains about 80% water. Although we utilize residues for recycling as described above, because they are carried to external processing facilities with a significant volume of water in them, they incur an environmental burden and an economic cost. Currently, the Company is researching and examining methods of applying fertilizer manufacturing technology to reduce the water content of residues without placing a load on the environment.

In addition, we are looking at switching to environmentally friendly packaging materials considering the strengthening regulations, such as the enforcement of the Act on Promotion of Resource Circulation for Plastics.

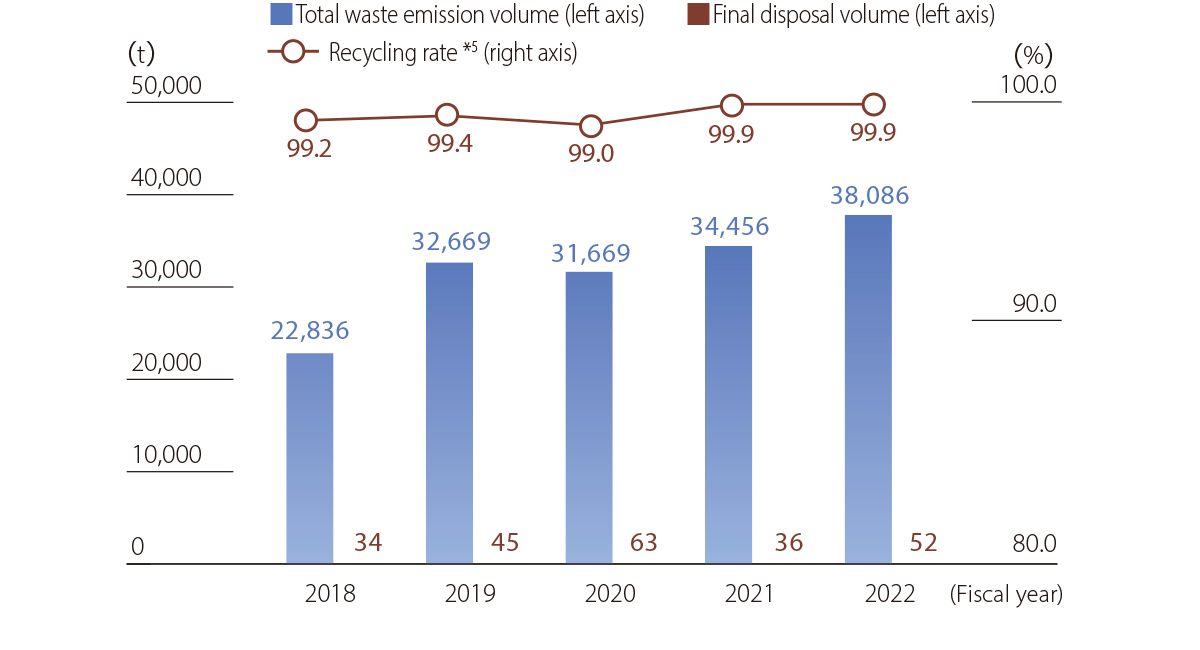

Total waste emissions, final disposal volume, and recycling rate

-

Note: Waste includes industrial waste (including ones under special management), as well as municipal solid waste.

*5 Recycle rate = recycled volume/total waste emission ×100